In its June 2014 report, Making in America: U.S. Manufacturing Entrepreneurship and Innovation, the authors from the Executive Office of the President state:

In its June 2014 report, Making in America: U.S. Manufacturing Entrepreneurship and Innovation, the authors from the Executive Office of the President state:

Manufacturing matters because of its outsized role in anchoring and fueling the American innovation economy.

Manufacturing, while accounting for just 12% of the GDP, makes up for 60% of all private sector U.S. research and development employees, and contributes 75% of private sector research and development.

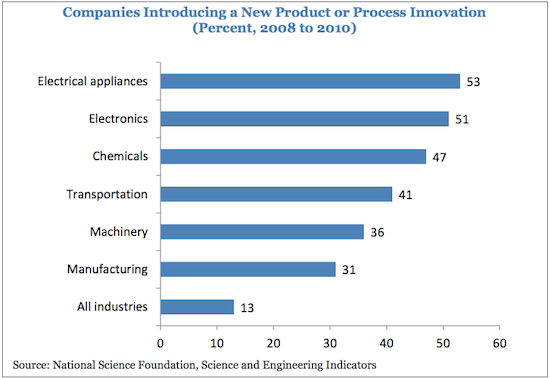

Manufacturing firms in the U.S. innovate at a rate two times that of other U.S. businesses — over 30% of U.S. manufacturers reported an innovation — the introduction of a radically new product or process — in 2010, compared to only 13% of other businesses.

Manufacturers of communications equipment, aircraft and spacecraft, pharmaceuticals, and computers report rates of innovation that are at least double the U.S. manufacturing sector average. (pgs. 6 – 8)

Innovation comes in many forms

After coming off of 10 years of investment stagnation and the off-shoring of millions of production jobs, U.S. manufacturing is on a resurgence — with the U.S. adding 646,000 manufacturing jobs since February 2010.

In fact, I have a front row seat to this show: My own manufacturing clients continue to grow sales and more importantly, add to their workforces. Good news indeed!

The main stream media has done a terrific job of telling the stories of manufacturing’s role in the innovation economy. On any given day you can find at least one story of a manufacturing concern or an entire industry that’s growing due to innovation. I’ve listed a few here.

Textiles

Diverse Woodworking

One company that’s growing due to improved technology is Diverse Woodworking in Indiana. Co-founder Randy Elliot began making bird-houses in his garage seven years ago. What started as a hobby has now grown into a woodworking operation that’s housed in a 4,000 square foot plant. The company manufactures over 150 products using high-tech precision wood cutting machines. (Source: WDRB.com)

Embroidery companies

No longer are older women with arthritic fingers sewing satin stitches that make up logos on team and B2B apparel. New innovations, according to Florida Weekly‘s article, “Stitching for a Living,” include water-based ink printing on garments that’s then heat cured, as well as machines that cut and stitch. Thanks to new technologies, these small shops are “slammed” with work, according to the article.

Metal parts fabrication

Anderson Industries

Founded by Kory Anderson in 2008, Anderson Industries recently moved into an 110,000 square foot facility. Anderson first started by servicing heavy equipment but, after purchasing a CNC machine, began making foundry patterns for a company in South Dakota. Anderson has since added other services and now employs 180 people. (Source: Prairie Business)

Acme Wire Products

Thanks to auto manufacturers wanting to add new gears to vehicle transmissions, Acme Wire Products is on the forefront of creating wire baskets automation companies need. Acme Wire manufactures the baskets using a specialized machining process. The company is so busy, it’s had to add a third shift. (Source: Acme Wire Products)

Scrap Metal Recycling

Did you know the U.S. leads the way in terms of scrap metal recycling? Yep. We recycle everything from automobiles and white goods to old cooking grills and even Christmas tree lights (the strings of lights are broken down for the copper).

As virgin metal becomes more scarce and expensive to mine, U.S. companies have stepped up to create better and more efficient ways to recycle and reuse metals such as iron and aluminum. According to State Metal Industries, every ton of aluminum recycled saves:

- 1,663 gallons of oil

- 14,000 kWh of electricity

- 237 million Btu’s of energy

- 10 Cubic yards of landfill space

For a great read on the state of recycling in the U.S. and around the globe, be sure to check out Adam Minter’s Junkyard Planet: Travels in the Billion-Dollar Trash Trade. Five stars.

Systems and Components

Marotta Controls

Founded 43 years ago, Marotta Controls created the control valves for the rocket that powered Chuck Yeager’s supersonic flight in 1947. Today the company’s innovative technologies continue to push boundaries in defense, space, and aerospace. (Source: NorthJersey.com)

The bottom line: Manufacturing is our past, present and future

“It is increasingly understood that not only our strengths today, but our future strengths in innovation as well, depend on retaining the knowledge and know-how that come from manufacturing,” the report authors state.

Are you a small industrial manufacturer with a good story about your innovative processes you’d like to share? If so, I’d love to feature your story on this blog. Please email me or call. If you’re within driving distance, I’ll come visit you.